| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Horizontal Vacuum Pyrolysis Cleaning Device | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

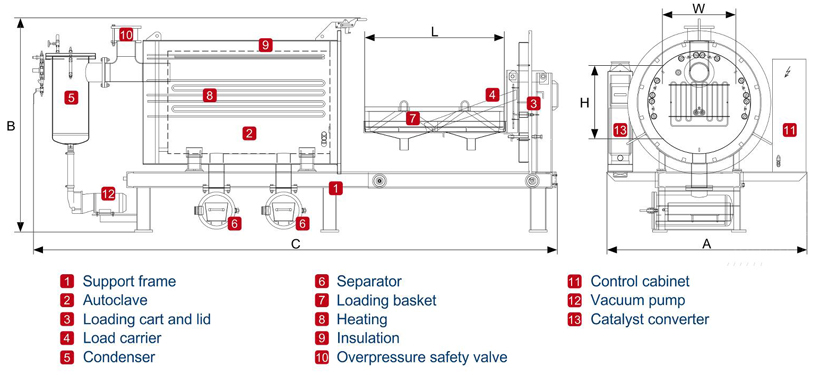

Horizontal Vacuum Pyrolysis Cleaning Device HVPC-series Cleaning Objects: Spin-pack or Filter of PET、PA6/66 project; Cleaning Objects:    Principle: Vacuum Pyrolysis Cleaning device is designed specially for cleaning polymers from a variety of metal components. The parts to be cleaned are heated in a chamber where the polymer melts and drains into the bottom collector. Remaining polymer is vaporized and then water scrubbed in a secondary scrubber where condensates are collected and rush out with water. Since cleaning takes place under vacuum, combustion does not occur. The parts are protected from excessive or localized high temperatures. The whole process has no pollution. Specifications:

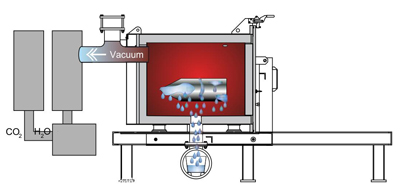

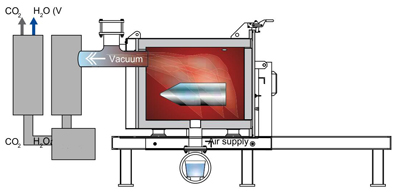

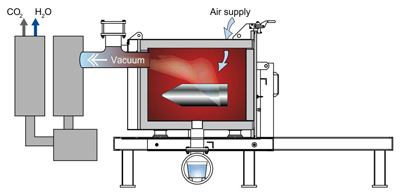

Cleaning Process:  A.Melting stage During heating up(150℃),the PET materials adhering to the spin packs to be cleaned first all become liquid but do not decompose thermally. The melting plastic flows via a discharge trough into the cooler melt container, where it can cool down and then be removed for the further porcessing stage.  B. Pyrolysis stage On reaching the decomposition temperature of the respective polymer,the heat output is regulated automatically in the process chamber in such a way that the best possible conversion is guaranteed in the catalytic converter.  C. Oxidation stage The oxygen is added to the process chamber to oxidise any remaining residues of the organic products of decomposition. Any remaining inorganic residues on the cleaned components can easily be removed mechanically.  Advantage: Vacuum pyrolysis cleaning device can not only be used for cleaning various types of spinneret; also widely used in components, shell, metering pump cleaning. And it can also be specialized cleaning the filter which the TEG cleaning cannot be done. Fully reflects its excellent cleaning results, low operating costs, and easy to operate, safety, environmental protection and other advantages. Equipment can be placed arbitrarily, easy to operate, good cleaning effect, the space requirements of the plant is relatively low. Other equipment advantages same as VVHP series. Users in the use of the process, do not need to heat decomposition spinneret components;components can be cleaned directly in the furnace;After cleaning, components can self decomposition. If necessary, the spinneret plate, distribution board, etc. can be cleaned again.  Scope:   | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||